Packing Tables manufactured in the UK

Designed to improve packing efficiency, these fully welded packing tables are made to the highest quality at our East Yorkshire factory.

Spaceguard is a manufacturer of robust workplace products including workbenches, warehouse packing stations, industrial guarding, and reliable conveyor systems.

New Product Range

Next day despatch Packing Tables

Available now from just £170

UK Manufactured Conveyor Solutions

We Supply and Manufacture Conveyors & Conveyor Systems

We regularly work with warehousing & logistics businesses to improve their good-in and despatch operations.

We will work with you to design and manufacture conveyors to suit your exact requirements, with equipment delivered fully assembled or installed by our on-site team. Many of our conveyor solutions are manufactured in-house in our East Yorkshire based factory.

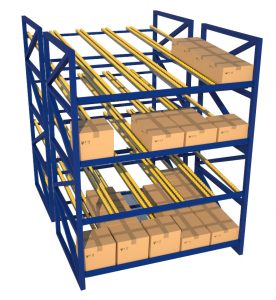

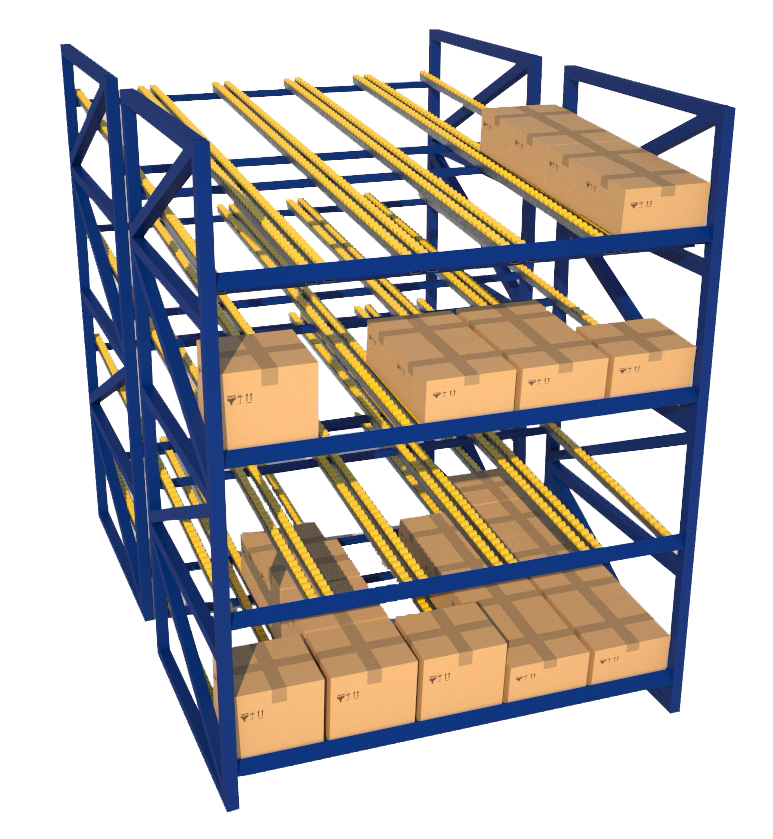

Bespoke Storage Racking

We manufacture fully bespoke storage & racking solutions including:

- Warehouse Racking

- FIFO / LIFO

- Adjustable Shelving

- Mobile Storage Racks

Get our Latest Brochure

Download our newest Packing Tables & Trolleys Brochure

Our Customers Include